Description

1、Brief introduction of fiber laser marking machine

1)Equipment features

The reaction mechanism of laser processing is realized by photochemical

ablation, that is to say, the bonding between atoms or molecules is interrupted

by laser energy to make them vaporize and evaporate into small molecules. UV

laser marking has the advantages of small focusing spot, wide application

materials, processing materials that absorb red light, etc. Mainly used in

high-end market of fine processing.

The beam quality is good, the focus spot is smaller, and fine marking can be

realized;

Most materials can absorb infrared laser, so they are widely used to make up

for the lack of machining ability;

Strong adaptability, fiber laser does not need water cooler, and its

stability is much higher than that of traditional laser equipment;

Marking speed is fast and efficiency is high;

The whole machine has stable performance, small volume and low power

consumption.

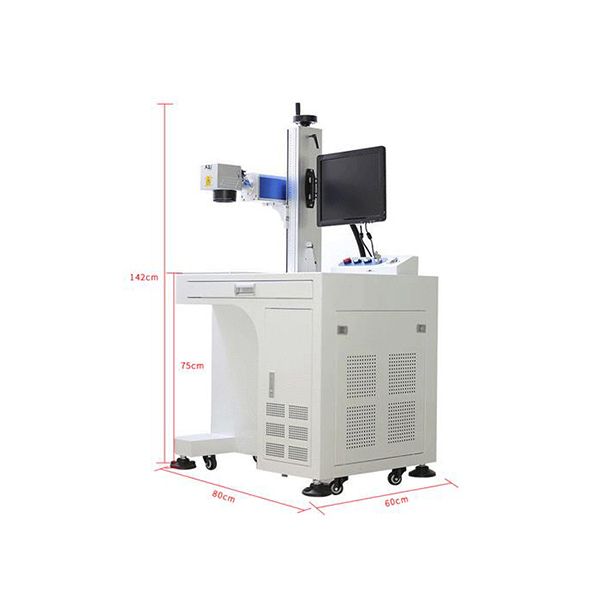

2、Equipment appearance

Dimensions: length 60cm * width 80cm * height 142cm;

(subject to the actual appearance)

1)Pulse width adjustable technical parameter

|

Model |

MZ-20M |

MZ-30M |

MZ-60M |

MZ-100M |

MZ-200M |

|

Maximum average laser power |

20W |

30W |

60W |

100W |

200W |

|

Laser repetition rate(Khz) |

1-4000 |

||||

|

Laser pulse width(ns) |

2-350 |

2-350 |

2-350 |

2-500 |

2-500 |

|

Laser wavelength |

1064nm |

||||

|

Beam quality M2 |

<1.4 |

||||

|

Standard engraving range |

100mm*100mm/150mm*150mm/175mm*175mm |

||||

|

Maximum line speed of engraving |

7000mm/s |

||||

|

Minimum line width |

0.05mm |

||||

|

Repeatability |

±0.03mm |

||||

|

Electricity demand |

220V±22V / 50Hz /10A/15A/18A |

||||

|

Power consumption of the whole machine |

<800W |

||||

|

working temperature |

0-40℃ |

||||

|

relative humidity |

<80% |

||||

2)Fixed pulse width type technical parameter

|

Model |

MZ-20W |

MZ-30W |

MZ-50W |

MZ-100W |

MZ-200W |

|

Maximum average laser power |

20W |

30W |

60W |

100W |

200W |

|

Laser repetition rate(Khz) |

27-80 |

20-200 |

|||

|

Laser pulse width(ns) |

80-120 |

80-120 |

80-120 |

150-270 |

150-270 |

|

Laser wavelength |

1064nm |

||||

|

Beam quality M2 |

<1.5 |

<2 |

|||

|

Standard engraving range |

100mm*100mm/150mm*150mm/175mm*175mm |

||||

|

Maximum line speed of engraving |

7000mm/s |

||||

|

Minimum line width |

0.05mm |

||||

|

Repeatability |

±0.03mm |

||||

|

Electricity demand |

220V±22V / 50Hz /10A/15A/18A |

||||

3. Sample Images

|

|

|

|

Mountaineering buckle carving |

Dog tag carving |

Logo carving |

|

|

|

|

Ring carving |

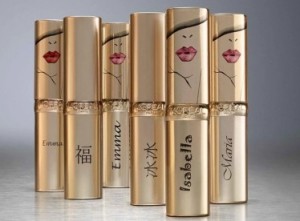

Cosmetics shell carving |

Aluminum carving |

4. Working Environment Requirements

1) Ambient temperature should be between 0-35°C, and air conditioning is

required;

2) Humidity should be between 45%-75%. No condensation is allowed, and a

dehumidifier should be installed;

3) Power supply requirements: 220V, 50Hz;

4) Power grid fluctuation: ±5%, and the grounding wire must comply with

international standards. In areas with voltage amplitude exceeding 5%, an

electronic automatic voltage and current stabilizer should be installed;

5) There should be no strong electromagnetic signal interference near the

installation site. Avoid radio transmission stations (or relay stations) in the

surrounding area;

6) Foundation vibration amplitude: recommended to be less than 50 µm;

vibration acceleration: recommended to be less than 0.05g. Avoid having a large

number of stamping or other machine tool equipment nearby;

7) The equipment space must be smoke-free and dust-free. Avoid environments

with severe dust, such as metal polishing or grinding;

8) Strict requirements for the quality of cooling water: purified water,

deionized water, or distilled water must be used. Tap water, mineral water, or

other liquids containing high levels of metal ions or minerals are not

allowed.

Reviews

There are no reviews yet.