Description

Profile

2507 is an ultra-duplex stainless steel containing 25% chromium, 4% molybdenum and 7% nickel. In terms of chemical composition, the chromium and molybdenum content of 2507 stainless steel is relatively high, which leads to its super-strong corrosion resistance to various acids. The duplex construction of 2507 stainless steel gives it excellent resistance in the face of stress corrosion cracking. Cracks are an inevitable problem in construction and other related fields, and 2507 stainless steel exhibits excellent corrosion resistance in an environment containing chloride ions, which makes it ideal for construction and related industries.

In addition to its excellent corrosion resistance, 2507 stainless steel also has excellent mechanical properties. It has high compressive strength, impact strength and low coefficient of thermal expansion, which makes it widely used in oil and gas industry, water treatment, fire protection, desalination equipment, mechanical parts and fuel gas purification equipment

Product Description

|

Product |

2507 Duplex Stainless Steel Plate |

|

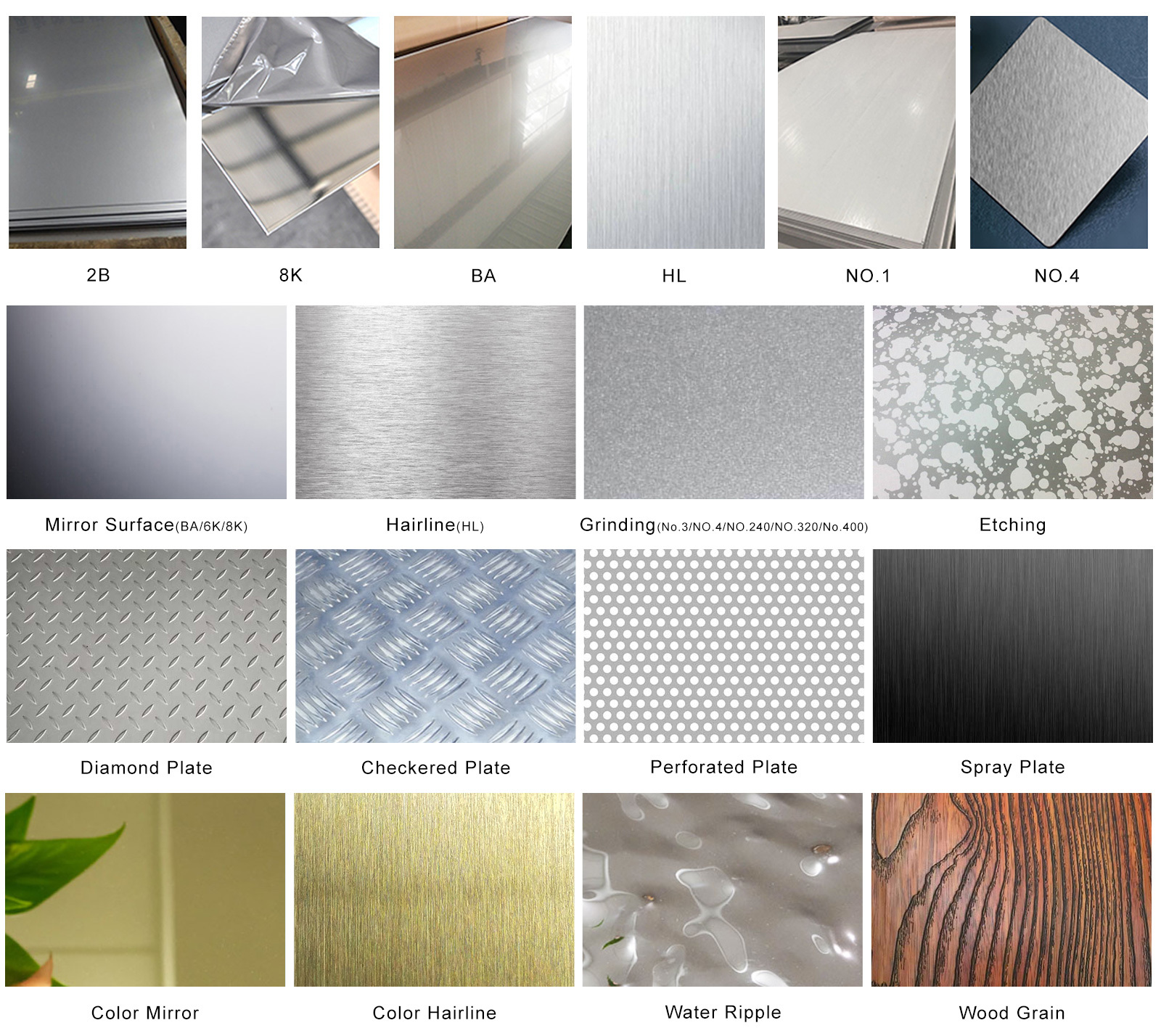

Surface Finish |

BA, 2B, 4K, 6K, 8K, NO.4, HL, Embossed, Perforated, Pickling white, Polished outside, Polished inside and outside |

|

Technique |

Hot Rolled / Cold Rolled |

|

Standard |

AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc |

|

Width |

500mm/1000mm/1219mm/1250mm/1500mm/1800mm/2000mm/2200mm/2500mm/3000mm/3500mm, or as required |

|

Length |

500mm/1000mm/2000mm/2438mm/2500mm/3000mm/6000mm/8000mm—13000mm, or as required |

|

Thickness |

0.4/0.5/0.6/0.7/0.8/0.9/1.0/1.2/1.5/2.0/2.5/3.0/4.0/5.0/6.0/8.0/10.0/12.0/14.0/16.0—250mm, or as required |

|

Material |

201, 202 |

|

Color |

Standard RAL color: Red, Blue, White, Grey, Brick, etc. |

|

Stock Dimension |

Cold Rolled: 0.4-6.0mm*1000*2000mm/ 1220*2440mm/ 1250*2500mm/ 1500*3000mm, or as your request |

|

Service |

OEM, Customized processing service, Customized fabrication by drawings |

|

Processing Type |

Cutting, Bending, Stamping, Welding, CNC machining |

|

Cutting Type |

Laser cutting; Water-jet cutting; Flame cutting |

|

Protection |

1. Inter paper available |

|

Application |

Costruction Industry/ Kichten Products/ Fabrication Industry/ Home Decoration |

Chemical Composition

|

C |

Si |

Mn |

Cr |

Ni |

Mo |

S |

P |

|

≤ 0.03 |

≤ 0.8 |

≤ 1.2 |

24.0~26.0 |

6.0~8.0 |

3.0~5.0 |

≤ 0.02 |

≤ 0.035 |

Mechanical Properties

|

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

|

≥795 |

≥550 |

≥15 |

≤ 310HB |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

7.75 |

200 |

13.0 |

17.0 |

80 |

Surface Selection

Reviews

There are no reviews yet.